・ Improving 3K workplace for human resources

・ Stabilize quality and reducing time

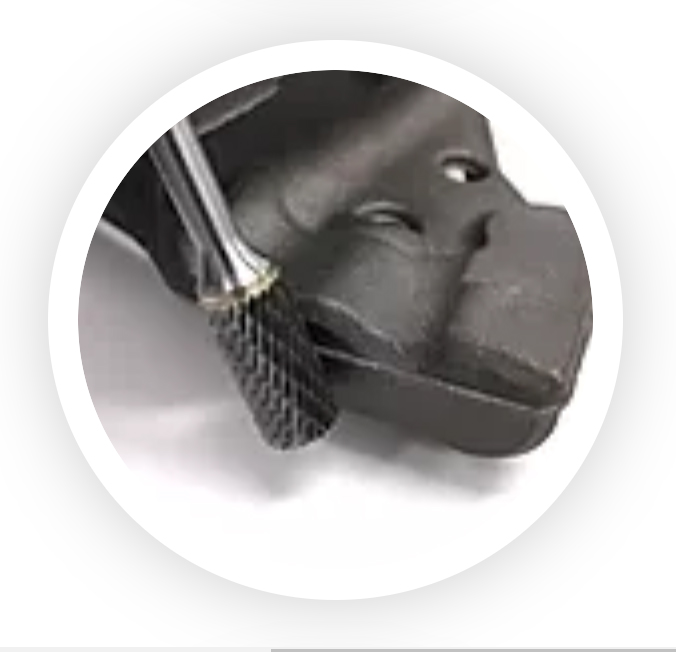

・ Mechanize grinding of narrow parts

・ Simply saving labor cost

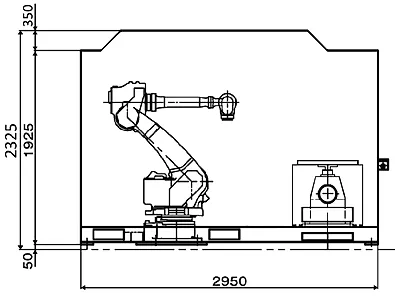

| Work weight | Maximum 30kg * Including work jig |

| Work size | 400mm or φ500mm x H300mm or less |

| Handling arm | 6-axis vertical articulated robot |

| Degree of freedom | 7 axes (Robot 6 axes + index table) |